Next Generation Epitaxy

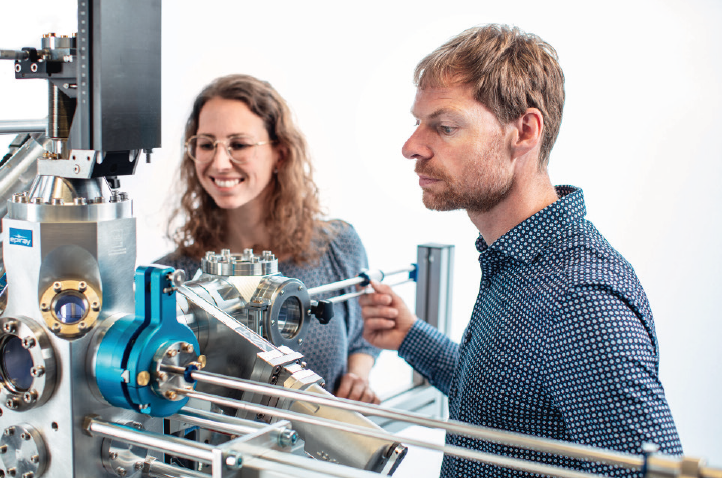

epiray introduces Thermal Laser Epitaxy (TLE) – a novel technology for the deposition of high-purity thin films. Epiray is a spin-off of the Max Planck Society pioneering a new era of epitaxy research.

A new deposition technology that will significantly impact thin film research and production.

TLE adds significant flexibility and speed to thin-film research. Sources can be changed rapidly without breaking the vacuum, and almost any material can be used. Layers of ultra-high purity can be deposited even in extremely reactive atmospheres. Operating costs are low.

It allows to conduct many more experiments in a given timeframe, with more diverse elements, than any other epitaxy method on the market. Boost your research with TLE!

Learn more about our technology or check out our TLE system or laser substrate heater for thin film deposition system upgrades.

Latest news

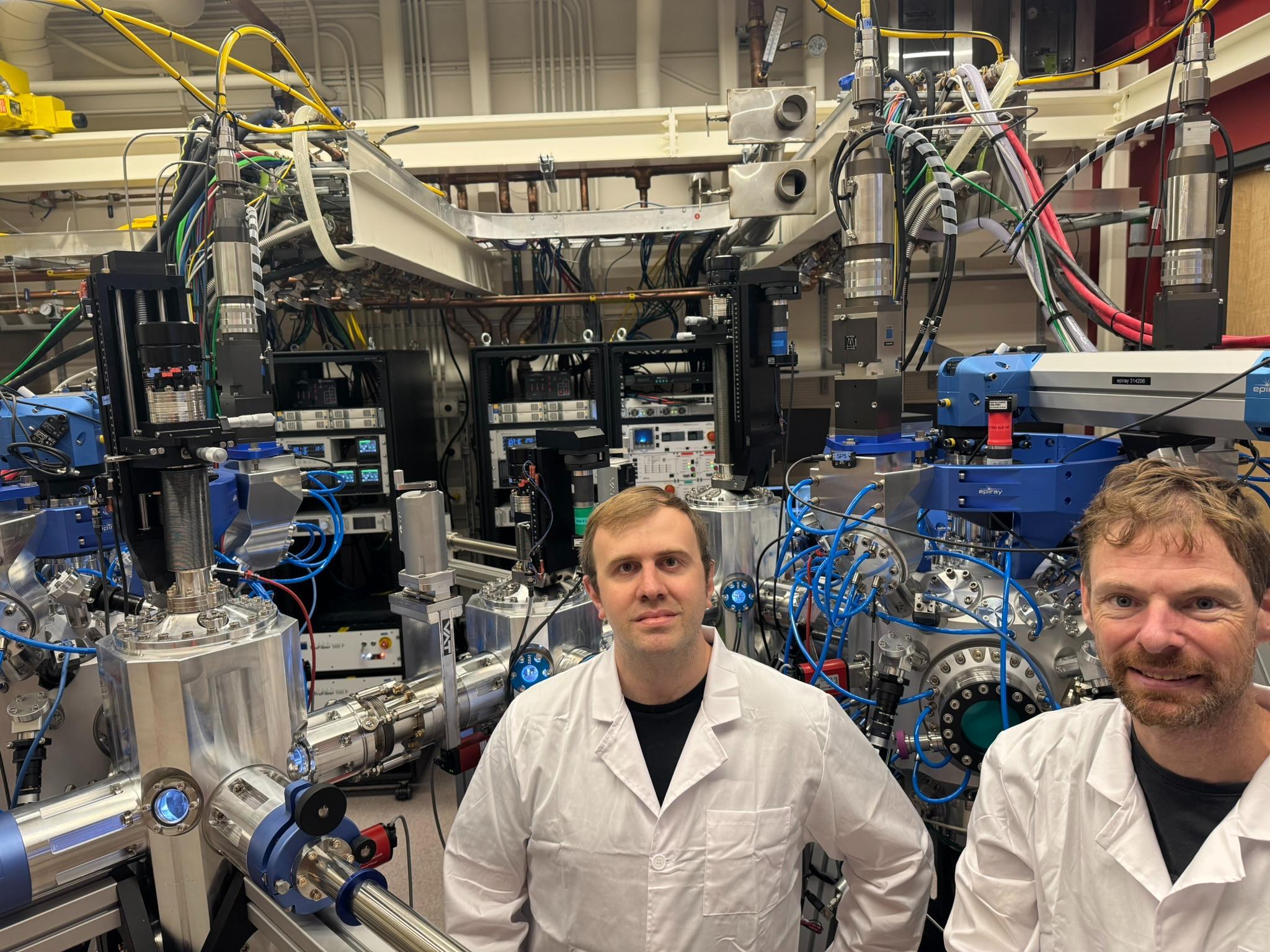

Epiray is thrilled to share a major milestone: completed commissioning of our first dual-chamber STRATOLAS Thermal Laser Epitaxy (TLE) system.

We're really excited to see the discoveries this platform will enable, and proud to be expanding TLE capabilities for the U.S. materials science community.

TLE science

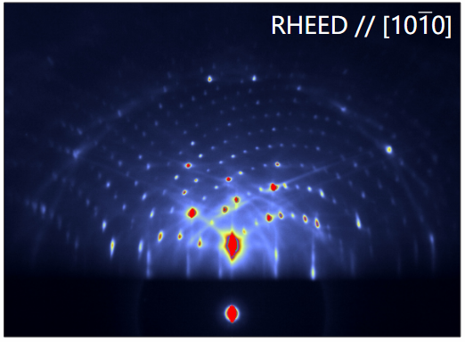

In-situ heating to extreme temperatures results in perfect surfaces for subsequent epitaxy. The image shows the RHEED pattern of a singular orientation of the sapphire surface reconstruction.

This work was recently published in Advanced Materials.

Products

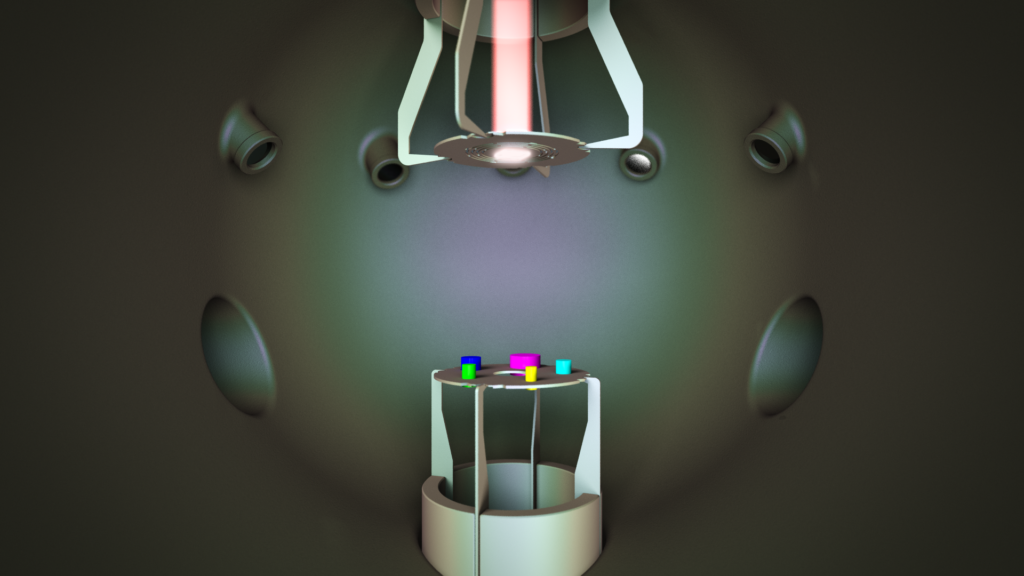

Our current product range consists of a complete TLE system (laser system with specialized vacuum chamber) and a laser heater for upgrading deposition systems to take advantage of our substrate heating technology. The laser heater can be used later as basic component to build up our TLE system.

STRATOLAS TLE System

THERMALAS Substrate Heater

Technology

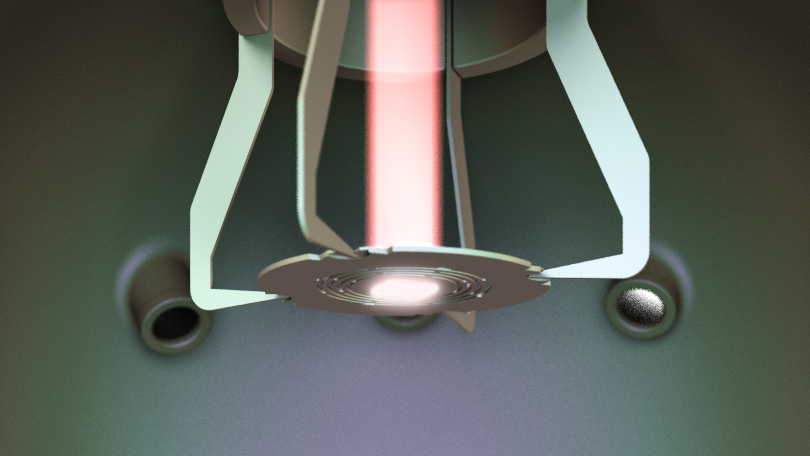

Source evaporation by lasers

High-purity elemental sources are thermally evaporated by laser radiation. All elements can be evaporated within the same setup.

Laser substrate heating

With the direct light absorption by long-wavelength lasers, substrates can be heated in an ultrapure environment up to extremely high temperatures.

Vacuum technology and design

Epiray’s vacuum design strategy is specifically optimized for TLE. The chambers are compact with a minimalistic design.

Company

epiray was founded in 2021 and is a spin-off of the Max-Planck-Institute for Solid-State Research in Stuttgart, Germany.